A high-performance and versatile solution

The exterior wall insulation products offered by Myral are made in France. They are certified and the subject of a technical advisory note by the CSTB (French scientific and technical centre for the construction industry), for all façade insulation needs of multi-dwelling units or single-family houses, office buildings or public facilities, for new builds or refurbishment.

They adapt to different types of surfaces: concrete masonry, wood, asbestos-containing surfaces or even as an adjunct and for restoring an existing thin rendering. They can be fitted vertically and horizontally.

They fully meet current thermal performance requirements and reflect the desire to use biosourced materials in constructional systems thanks to solutions adapted to fitting on timber frameworks or timber frame houses and the use of raw materials sourced from recycling.

It is a solution that contributes by and large to the renovation of buildings, in the same way as roofing insulation solutions, heating systems, CMV, solar panels, energy management systems, joinery, etc.

The patented attachment system avoids thermal bridges and treats the framework's structural thermal bridges.

Specifications and performance of the products

- New generation polyurethane insulant (P-I-R) incorporating a proportion on biosourced material

- Aluminium panel Pre-lacquered (coal-coating)

- Aluminium vapour barrier

- Patented system of PVC fixing edges

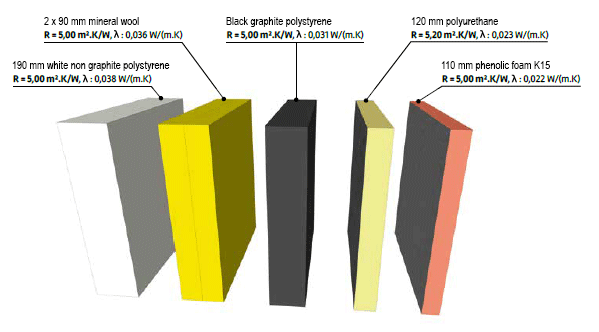

What insulating reinforcement to choose according to the type of building and fitting method?

What are their advantages according to configuration?

New generation polyurethane insulant (P-I-R) incorporating a proportion on biosourced material

- Excellent mechanical strength: density 55 kg/m3

- The best thermal efficiency on the market: Lambda 23 mW/m².K.

- 2 thicknesses of insulating material: 32 and 62 mm

Aluminium panel Pre-lacquered (coal-coating)

- Thickness of the aluminium: 5 or 7/10ths

- Wide selection of appearances and aesthetic finishes

Aluminium vapour barrier

- Boosts the already very high Sd value of the system

Patented system of PVC fixing edges

- exclusive interlocking process with thermal bridge breakage

- asy quick-fit interlocking system over the entire length

- Easy to cut (with a VL jigsaw)

- Can be fitted in any weather conditions

- Watertight (a combination of rigid and flexible PVC)

- Exclusive thermal bridge breakage joining system

Additional or reinforcing insulant

The first bed of insulant depends on the constructive system, therefore on the base material, the type of building, the constraints of the building site (seismic, wind, etc.) and the desired level of performance…

POLYISOCYANURATE, EPS, KOOLTHERM K15 RESYLIC FOAM, RIGID MINERAL INSULANT (rating I3)…

| Product performance | M32 Coef. (R) | M62 Coef. (R) |

|---|---|---|

| Panel alone | 1,35 | 2,65 |

| M32+Reinforcement 60mm | 4,05 | - |

| M32+Reinforcement 80mm | 4,95 | - |

| M32+Reinforcement 90mm | 5,40 | - |

| M32+Reinforcement 100mm | 5,85 | - |

| M32+Reinforcement 110mm | 6,35 | - |

| M32+Reinforcement 120mm | 6,80 | - |

| M32+Reinforcement 220mm | 11,35 | - |

Technical specifications

- Strips of 1.5 to 14 m, made to measure

- Effective width: 500 mm and fixed

- Weight: M32 : 3,8kg/m² - M62: 5,7kg/m²

- Thermal performance of the cladding alone: M32 : R 1,35, M62 : R 2,65

- Fire rating of the M32 facing: M1 – Bs2d0

- Impact rating: Q3 and Q4 (structured 7/10ths)

- Lining rating: E4 for vertical, horizontal or oblique fitting

- Wall type: XIV for vertical or horizontal fitting

- Approved LEPIR II: Test approved with M32 cladding + reinforcement

- Strips of 1.5 to 14 m, made to measure

- Effective width: 500 mm and fixed

- Weight: M32 : 3,8kg/m² - M62: 5,7kg/m²

- Thermal performance of the cladding alone: M32 : R 1,35, M62 : R 2,65

- Fire rating of the M32 facing: M1 – Bs2d0

- Impact rating: Q3 and Q4 (structured 7/10ths)

- Lining rating: E4 for vertical, horizontal or oblique fitting

- Wall type: XIV for vertical or horizontal fitting

- Approved LEPIR II: Test approved with M32 cladding + reinforcement

What insulating reinforcement to choose according to the type of building and fitting method?

What are their advantages according to configuration?

Versatile, easy and quick to implement

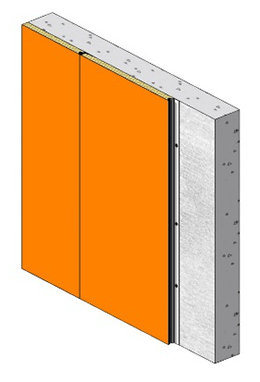

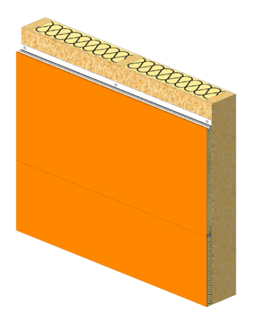

- Cladding on masonry base

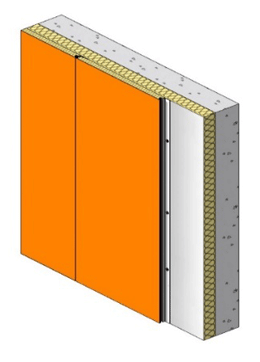

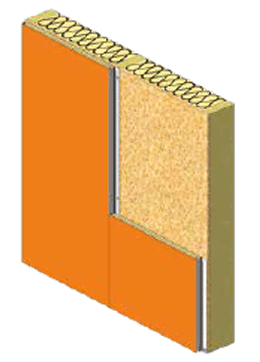

- Cladding on additional insulant on masonry base

- Fitting on timber framework or timber frame house/Additional insulation and finish

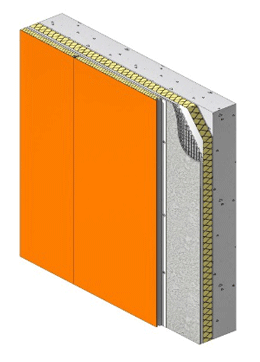

- Non-ventilated cladding / High thermal performance R > 12.6 on masonry base

Flatness, fire hazard, asbestos-containing surface, seismic risk?

Insulating weatherboarding on faced base material: supplementary insulation

Fitting

Fix directly to the M32 or M62 panel on the base material thanks to the PVC thermal bridge breakage edge (without framework, rail or hook), only with mechanical fastenings.

- External Wall Insulation can be combined with Internal Wall Insulation

- R=1.35 or R=2.65 can be achieved

- Can be fitted on a faced or brickwork base material

- Technical solution for efficient, simple, rapid and sustainable EWI

- A 2-in-1 solution with an aesthetic insulating head joint that offers thermal bridge breakage on the façade

Ordinary weatherboarding on faced base material: A high-performance, simple and rapid solution

> On concrete base or non-insulated brickwork

Fitting

Myral façade cladding panels are applied onto supplementary added insulating material, without a framework or air space. They are fixed through the PVC edge directly into the bearing wall with bolts going through the supplementary insulation.

- On a reinforcing insulating panel (max. width: 220 mm)

- Maximum thermal resistance: 12.6

- No primary framework: cheaper and easier to fit

- No air space management

- Fire breaks eliminated (Lepir 2)

- Bare to bare Among the thinnest on the market in relation to the resulting thermal performance

- Meets the following thermal requirements: BEPOS, EFFINERGIE, RT 2012, RT 2020, E+C-…

> On existing external wall insulation (thin insulating rendering)

Fitting

Myral façade cladding panels are applied onto existing insulation (existing external wall insulation in thin insulating rendering), without a framework and without air space. They are fixed through the PVC edge directly into the bearing wall with bolts going through the supplementary insulation.

- Remedial solution, according to A.T. (extensive renovation)

- Possibility of adding a minimum of M32 with supplementary insulant for a minimum R of 3.70 (EEC aid)

- Avoids stripping the existing external wall insulation

- No primary framework: cheaper and easier to fit

- No air space

- Bare to bare among the thinnest on the market in relation to the resulting thermal performance

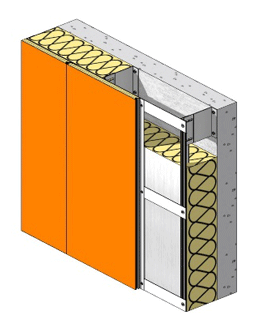

Fitting on timber framework or timber frame house : Additional insulation and finish

> Fitting as insulating weatherboarding on timber framework or timber frame houses

Fitting

M32 or M62 panel fixed directly onto the timber framework upright with mechanical fastenings.

- The panel can be fitted horizontally: no constraints with a spacing of 60 cm between the uprights

- The panel can be fitted vertically: as they must be fixed in the uprights, the spacing between the uprights must be 50 cm (namely the width of the boards)

- Also meets requirements for industrialized solutions with in-workshop fitting

- Vertical fitting as insulating weatherboarding

> Fitting as non-ventilated cladding on timber framework or timber frame houses

Fitting

On timber framework or timber frame houses: a bed of insulant is inserted between added battens. The Myral cladding is fixed directly onto the battens.

This method is only used for fitting the panels vertically, in order to retain a spacing of 60 cm between the uprights (the normal spacing adopted by the manufacturers).

- Enhances the performance of the timber frame structure

- Watertight

Non-ventilated cladding: High thermal performance R > 12.6 on masonry base

Fitting

Put in place a primary framework, fix the panels to the framework's uprights, insert an insulant between the uprights up to the back of the panels and block up the air space.

- Useful for covering recesses or unevenness on the façade

Specifics or benefits of the solution

- Optimal treatment of junction or structural thermal bridges

- An industrialized solution delivering panels made to measure (in steps of 1 cm)

- Almost no cutting required on site

- A lightweight product easy to handle that does not weigh down the structure of the building (4 kg/m² in 32 mm - 6 kg/m² in 62 mm)

- Can be fitted in any weather conditions

- Optimal fitting of the Myral solution as insulating or ordinary weatherboarding, without a primary framework, L-bracket or hook

- Can be used both on new builds and for renovation

- seful life estimated at 40/50 years (according to EPD data)

- Meets BEPOS, EFFINERGIE, RT 2012, RT 2020, E+C- thermal requirements and the requirement to combine it with biosourced and recycled raw materials

Base materials

- Concrete

- Masonry

- Brickwork

- Timber framework or timber frame houses

Fitting methods

- Vertical, horizontal or combined arrangement with mechanical fastenings suited to the base material

Flatness, fire hazard, asbestos-containing surface, seismic risk?

An architectural solution combining flexibility and elegance: Myral is the chameleon of the façade!

- Looks

-

The ranges of finishes

(pure matt, material effects, vision, timeless, head joint) - The outstanding points

Myral is an exterior insulation solution that fits all budgets.

Contact the specifier in your region who will guide you

Looks

The ranges of finishes

The outstanding points

Starting points, windows and doors, corners in the same finish, same bath or one-piece corners made on site

Myral façade cladding is a veritable exterior thermal insulation solution that meets the needs and constraints of multi-dwelling units, single-family dwellings, commercial buildings or public facilities: in new builds or for renovation. It combines aesthetics, insulation and a bespoke render thanks to:

- its large panels ranging from 1.5 to 14 metres long

- its fitting options: vertical, horizontal or combined arrangement to adapt to and enhance the façade

- the fact that it can be used on its own or in combination with another type of exterior thermal insulation

- perfect flatness, achieved with the insulant

- invisible mechanical fastenings

- very discreet jointing between panels (overlapping joints)

- the numerous appearances and finishes of the facing, in an infinite number of combinations

Myral is an exterior insulation solution that fits all budgets.

Contact the specifier in your region who will guide you

A limitless solution

- Creating frescos on panels

- Treating curved surfaces

- Joint layout with “extruded joint” or “recessed joint” profile

- Fitted on metal plate, on the underside, on roofing or for shaping corners

Looking for a colour or rendering? The specifier in your region is at your disposal to present all the available finishes to you.

Can be fitted on metal plating

On the underside

On the roof

Corner shaping

Our creations

Looking for a colour or rendering? The specifier in your region is at your disposal to present all the available finishes to you.